The common chicken egg is a marvel of culinary versatility and nutritional goodness. Eggs are also in high demand in commercial and domestic kitchens across the planet. At any given moment there are at least 3 billion eggs in transit from hen to kitchen in sturdy egg trays that protect these delicate orbs and ensure safe arrival.

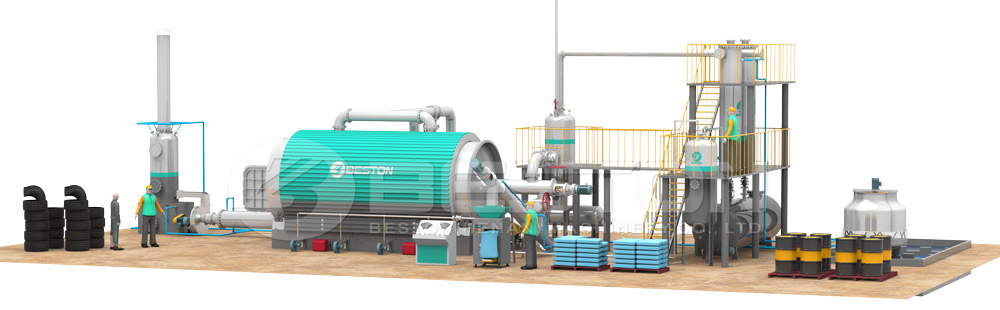

Beston Pulp Forming Machine for Sale

Because eggs are in high demand, so are the trays required to transport them to their final destination. To meet this demand, you will need a top-notch egg tray-making machine that integrates perfectly with your operations.

Here are some important considerations for choosing suitable egg tray equipment.

Quantity of Production

There is a great selection of different egg tray making machines suited to a wide range of different needs and capacities. You will need to ask yourself what you are hoping to accomplish in terms of production over time. Different types of egg tray making machines will have different production capacities. A larger and more powerful option might be able to produce over 6000 trays in a single hour. On the other hand, a smaller and more cost-effective option may produce 1000 or 2000 egg trays in one hour.

Budget Parameters

Once you know exactly what you need in an egg tray making machine, you will need to know exactly how much you are planning on investing in this project to expand your operations. This way you will be able to invest in a product that emphasizes the values you noted in step 1. Egg tray making machines have come a long way from their humble beginnings. Today’s modern machines feature various options that improve the suitability but also affect the egg tray manufacturing plant costs.

Affordable Pulp Forming Machine

Automated or Semi-Automated

One of the most important considerations will be choosing the level of attention needed by the egg tray making machine. The automated option is a great choice as it will reduce the costs of manual labor, but it will also represent a higher initial investment. On the other hand, a semi-automated option will not cost as much to acquire, but there will be the on-going costs of labor to operate a semi-automated egg tray making machine: https://pulpmouldingmachines.com/egg-crate-making-machine/.

Bespoke Manufacturing Plants

Before you have made your final decision, be sure to shop around and look at what is available from different manufacturers. There are many bespoke designs available that can suit your operational dynamics perfectly. You will want to make sure you have researched all the different components available from your egg tray making machine manufacturers before making a final decision. Furthermore, make sure you inquire about replacement parts, on-going maintenance, and repair services.